Investigation of Airflow Patterns and Thermal Efficiency in Different Ducting Configurations by using CFD

Keywords:

HVAC, ANSYS FLUENT, variable air volume, ducting systemAbstract

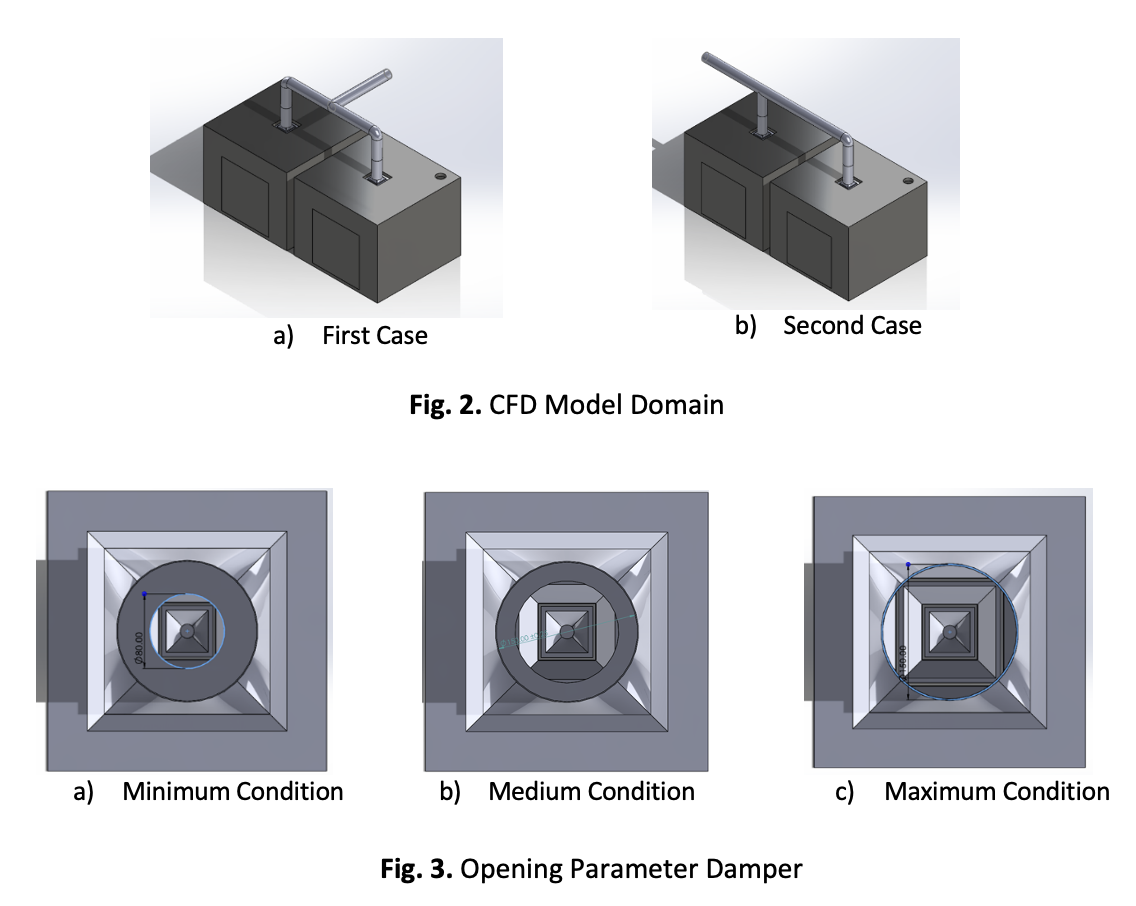

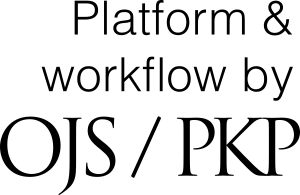

Centralized air-conditioning systems are essential for maintaining thermal comfort in commercial buildings, with Variable Air Volume (VAV) systems offering superior energy efficiency but facing operational challenges such as under or over-actuated conditions in different zones. These issues can lead to discomfort and energy wastage, impacting occupant productivity and building performance. This study employs Ansys FLUENT to design and evaluate Heating, Ventilation and Air Conditioning (HVAC) ducting systems, focusing on creating two configurations for thermal comfort analysis. Simulations with varied damper sizes ensure temperatures in Chamber A achieve the optimum temperature for thermal comfort, critical for consistent indoor conditions conducive to occupant comfort and productivity. The first design achieves uniform temperature and airflow distribution, indicating efficient cooling with minimal turbulence, while the second design requires optimization to match performance. Insights from damper size simulations provide practical guidance for real-world applications, emphasizing precise ducting design's role in enhancing thermal comfort and energy efficiency. Leveraging Ansys FLUENT enables detailed analysis and practical recommendations to optimize HVAC systems, contributing to improved indoor environmental quality and operational efficiency through advanced design strategies.