Understanding The Influences Of Different Ethanol-Petrol-Polyisobutylene Ratios To The Performance Of A Single Cylinder S.I. Engine

Keywords:

Single cylinder engine, Ethanol-blended fuels, PolyisobutyleneAbstract

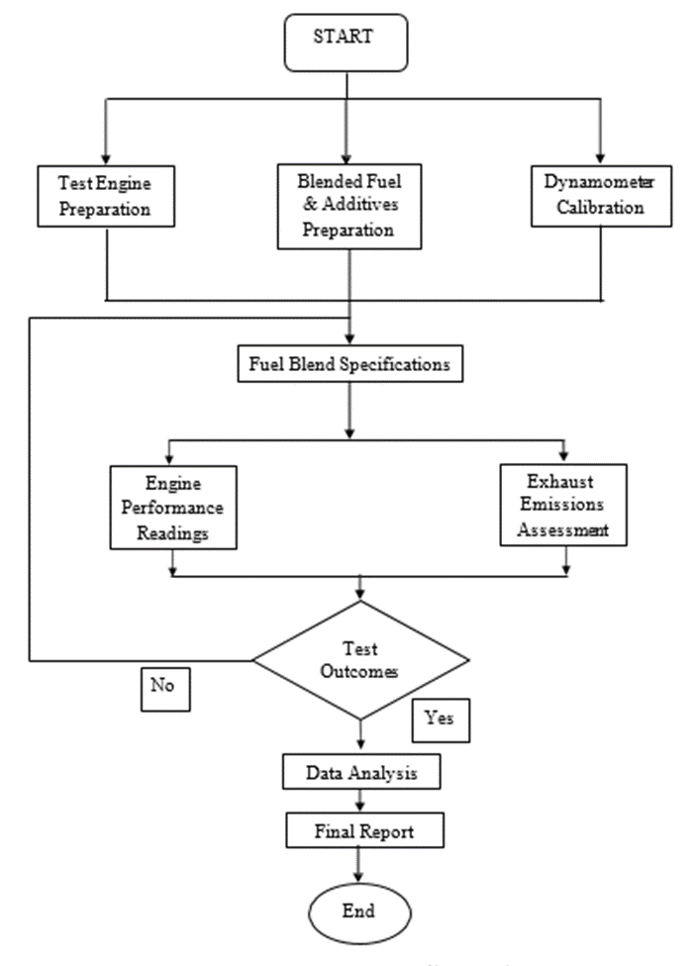

The project focused on the use of polyisobutylene (PIB) additive in ethanol-blended fuels (E5P1, E5P5, E25P1, E25P5) for a 150 cc spark-ignition engine. The experiments tested different fuel compositions at road speeds from 30 to 90 km/h under part-load (PL) and wide-open throttle (WOT) conditions. The results show that E5P5 achieved optimal torque at 60 km/h, while E25P1 had the highest torque at 50 km/h under WOT. For fuel consumption, E0 had the lowest BSFC at part-load, but E5P5 consumed 26% less fuel than E0 at 90 km/h. Ethanol's higher octane allowed for a leaner mixture without sacrificing performance. BMEP data showed E25P5 generated 30% greater BMEP than E0 at 50 km/h PL. In terms of BTE, E5P1 had the highest BTE at PL, while E25P5 had the highest at WOT. Ethanol's oxygen content improved combustion. As speed increased, E25P5 had lower emissions than other blends and gasoline, though it was not always the "lowest" polluting option.