Mesh Convergence Study of A106 Grade B Carbon Steel Pipe on Different Type of Ceramic Pads in Post-Weld Heat Treatment (PWHT)

Abstract

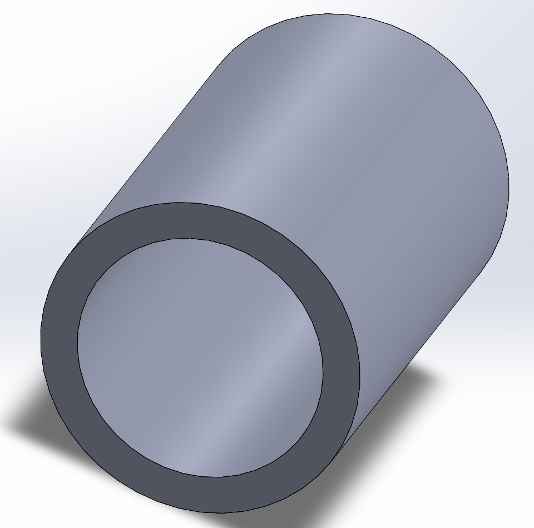

A mesh convergence study in finite element analysis was conducted using various mesh sizes to determine if the result varied. This study aims to obtain accurate data before comparing it with analytical results. A joining pipe with different types of ceramic pads, such as standard pad, thick wall pad, long strip pad, and short strip pad was modeled using Solidworks software. The thermal profiles and thermal expansion of the pipe were analyzed using various converged mesh sizes and mesh modes. A temperature of 650 ℃ was applied to the ceramic pad, as it acts as an insulator that spreads heat across the pipe. It was found that mesh number 10 (size: 0.05) was selected for the standard pad, and mesh number 6 (size: 0.13) for the thick wall pad, as the data had already converged, making the mesh size accurate and reliable with relative errors of 0.019% and 2.41%, respectively. For the long strip pad and short strip pad, mesh number 13 (size: 0.02), and mesh number 9 (size: 0.06) were selected as the most optimal meshes, providing a converged solution with minimal relative errors of 0.06% and 0.02%, respectively.